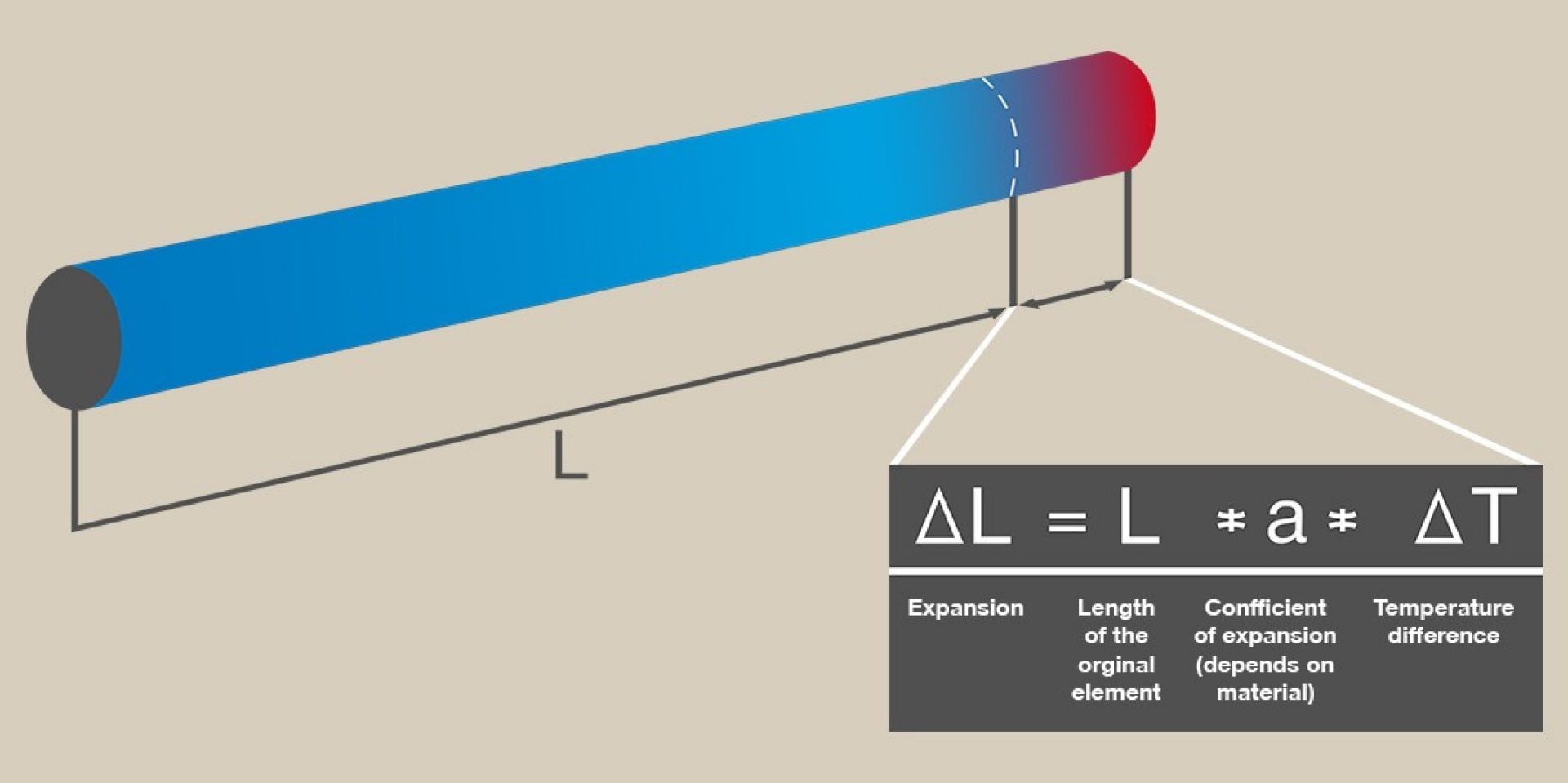

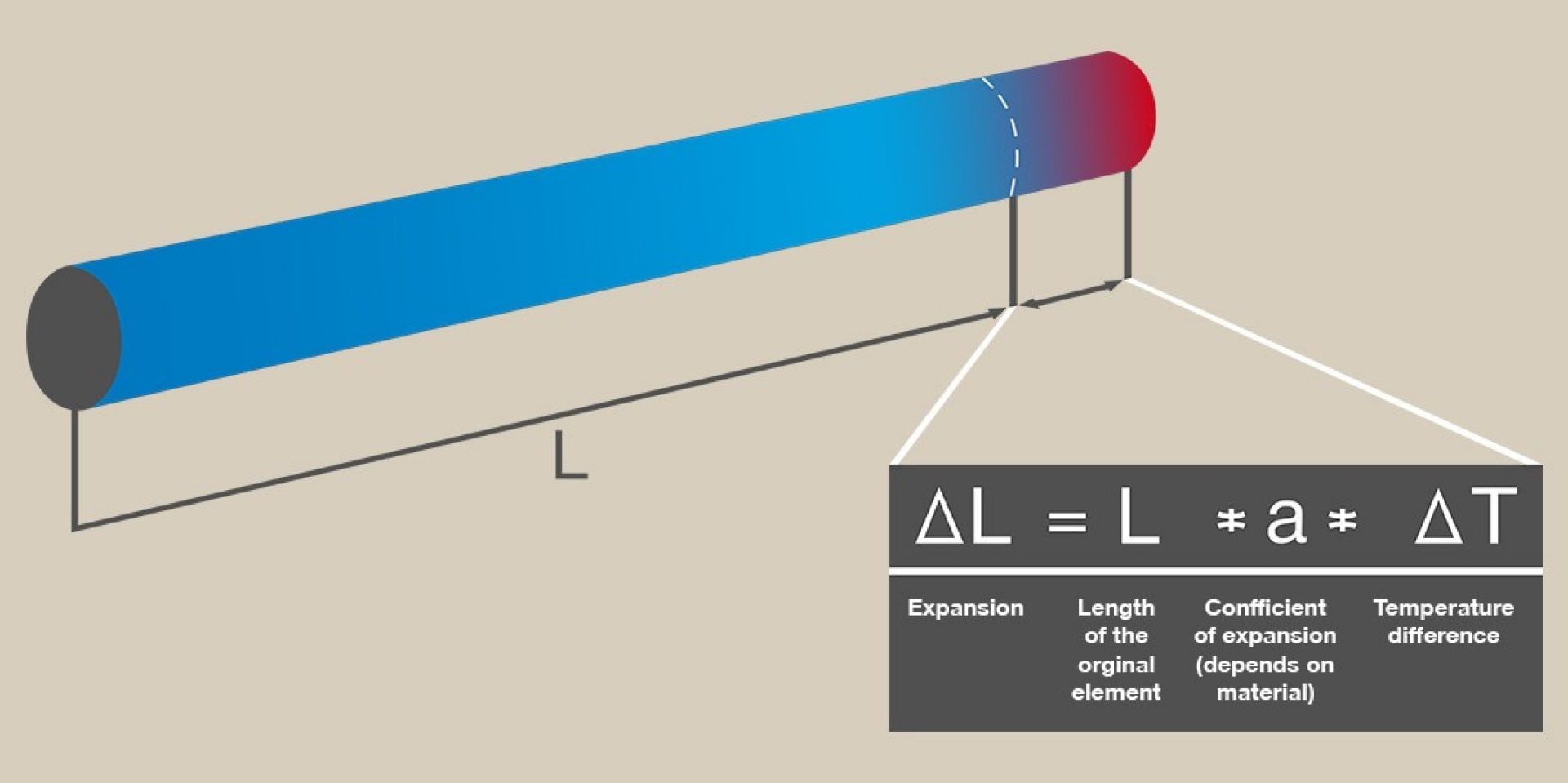

HOW TO DESIGN FOR THERMAL MOVEMENT

Thermal expansion design

RELATED SOFTWARE

Share this content

RELATED SOFTWARE

Share this content